Stamped parts usually require subsequent bending, punching, shaping, and other processes to achieve the shape and size required by the design. During the manufacturing process, issues such as material selection, mold design, and optimization of process parameters need to be considered to ensure that the quality and performance of stamping parts meet requirements. Automotive stamping parts are one of the most important components in automotive manufacturing, and their quality and performance are directly related to the safety, comfort, and economy of automobiles

- Manufacturing process: laser cutting, CNC stamping, CNC machining, stamping, bending, thread processing, welding, deep drawing, polishing, tapping, riveting, and assembly.

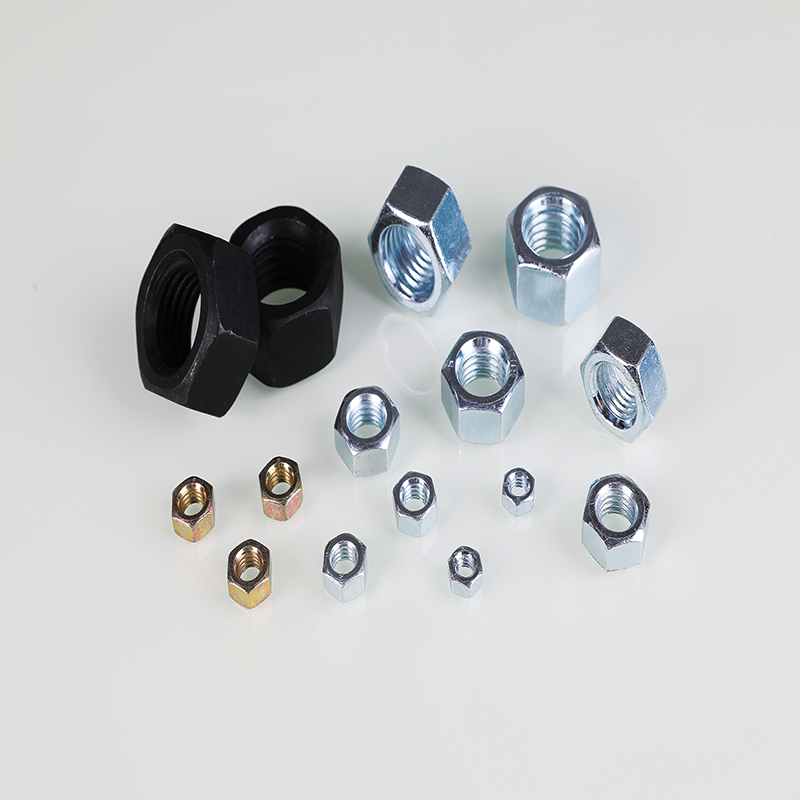

- Material: stainless steel, carbon steel, copper, aluminum, brass, iron, bronze (according to customer requirements)

- Surface treatment: zinc plating (zinc plating, nickel plating, chromium plating, silver plating), powder spraying, polishing (mirror polishing, electrolytic polishing), wire drawing, sandblasting, chemical etching, passivation treatment, etc.

- Applications: automotive components, vehicles, rail transit, engineering machinery, engineering machinery, food machinery, electrical equipment, etc

Our advantages:

1. Rapid response within 4 hours.

2. Manufacturers with 12 years of experience.

3. We are ODM&OEM, designed according to your drawings.

4. Rich experience and good technical support (engineers with more than 20 years of experience).

5. Manufacturers and trading companies.

6. Accept low minimum order quantity.

7. 100% inspection before delivery.

8. Competitive price and high quality.

9. Convenient transportation.

10. Certification: ISO9001:2022

How to contact us:

Jiaxing LianXin Auto parts Co.,Ltd

Address: NO. 188,YUANXIN LINE, YUANTONG STREET HAIYAN COUNTY, ZHEJIANG RPOVINCE

Contact person : Clover Li

Email: [email protected]

Mobile +86 18058633639 (WhatsApp/WeChat)

clear

clear